Spitfire CFD Simulation Benchmark

This benchmark project shows a complex CFD and FEA analysis of FDA pump using simulation environment TCAE

FEA Simulation Report

TCFD automated workflow

CFD SUPPORT introduces the new generation of CFD simulations. TCFD brings an extreme increase of productivity to CFD simulations. TCFD is extremely popular project, because it successfully merged benefits of an open-source (perpetual, unlimited users, jobs, and cores, customizable, …) with benefits of commercial codes (professional support, well tested, ready for the industry, robust, accurate, automated, GUI, …).

TCFD is fully automated, it can run the whole workflow by a single command: data input, new case is written down, mesh is created, case is set-up, case is simulated, results are evaluated and the results report is written down. Both GUI and batch mode. Data in – data out. TCFD is mainly focused on supporting the engineers in their real value added work. TCFD is fully automated and the beauty of TCFD is that it is the user who decides how deep to dive into a CFD or not at all. And all the options remain open at the same time.

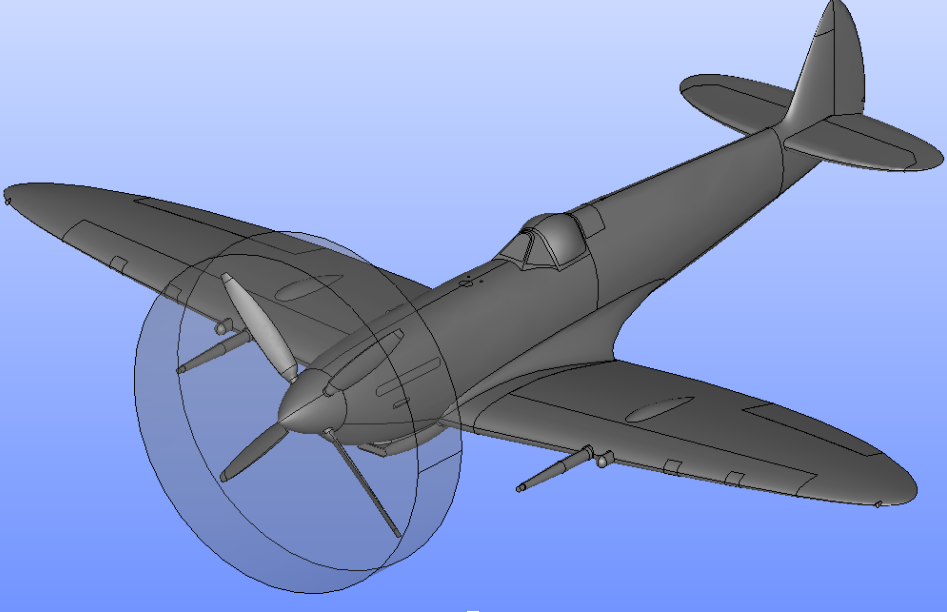

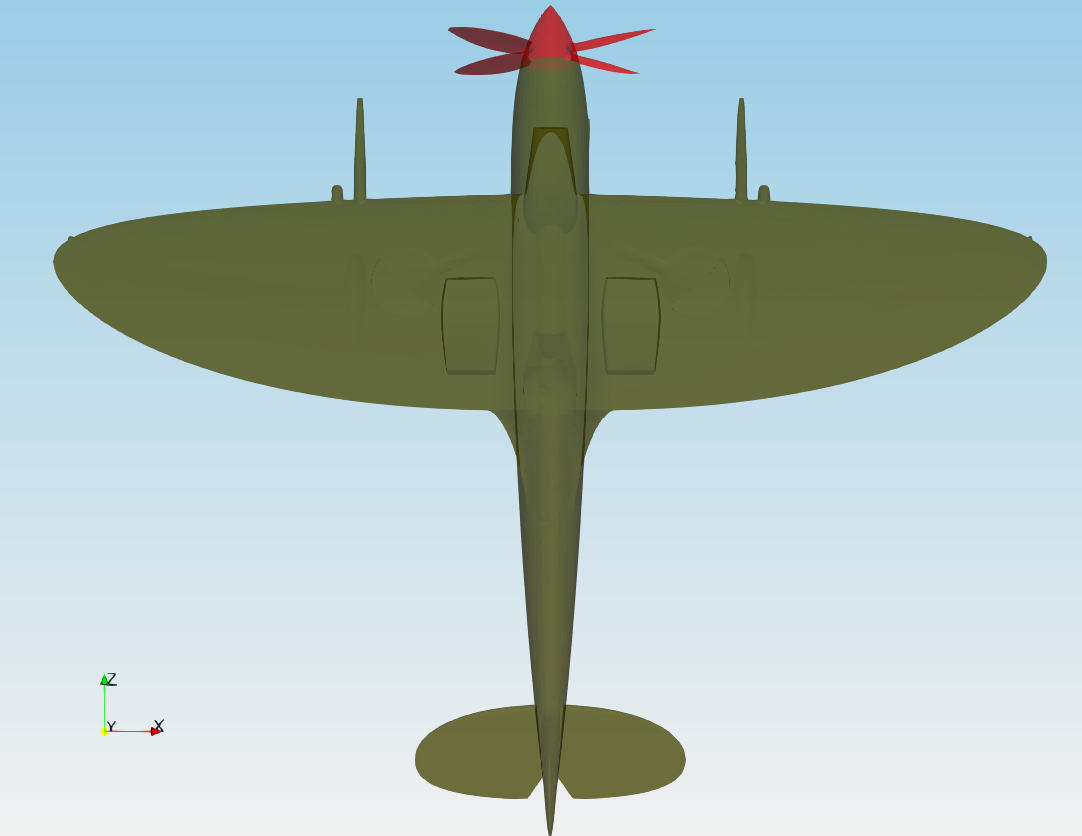

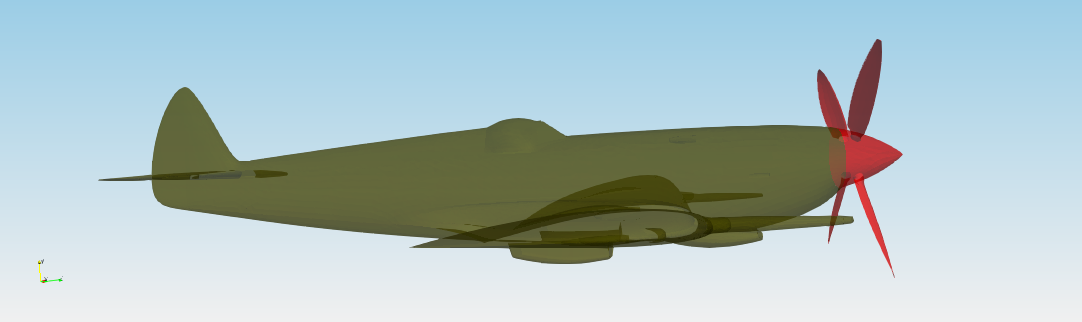

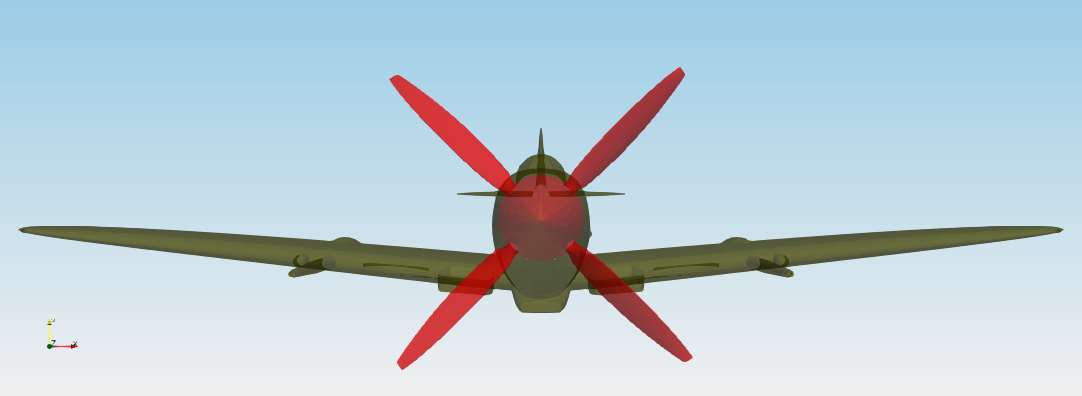

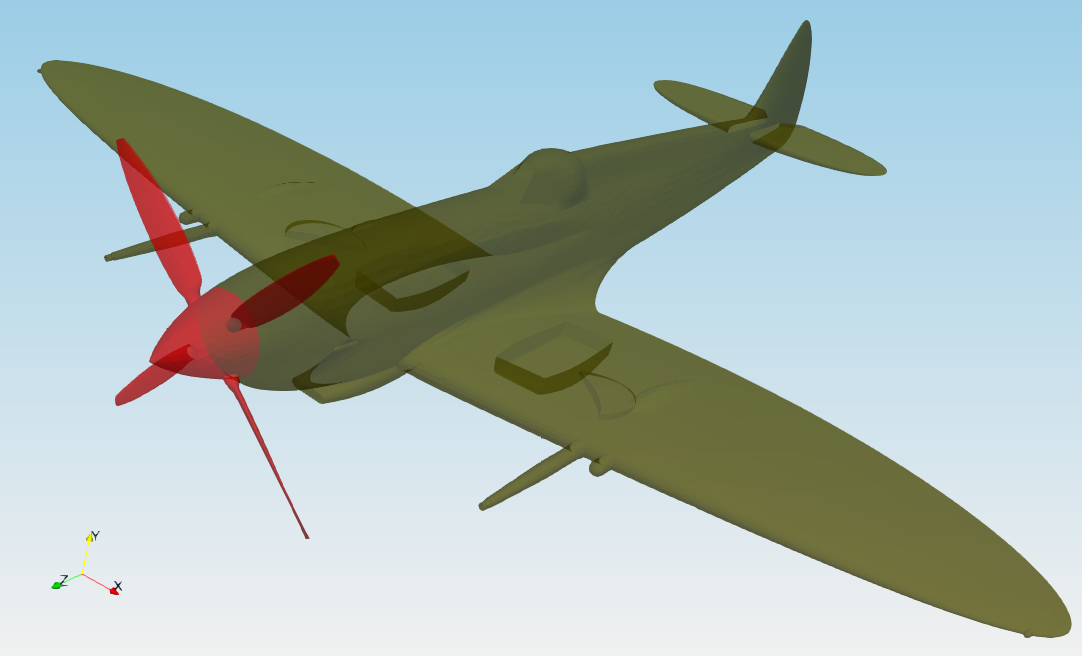

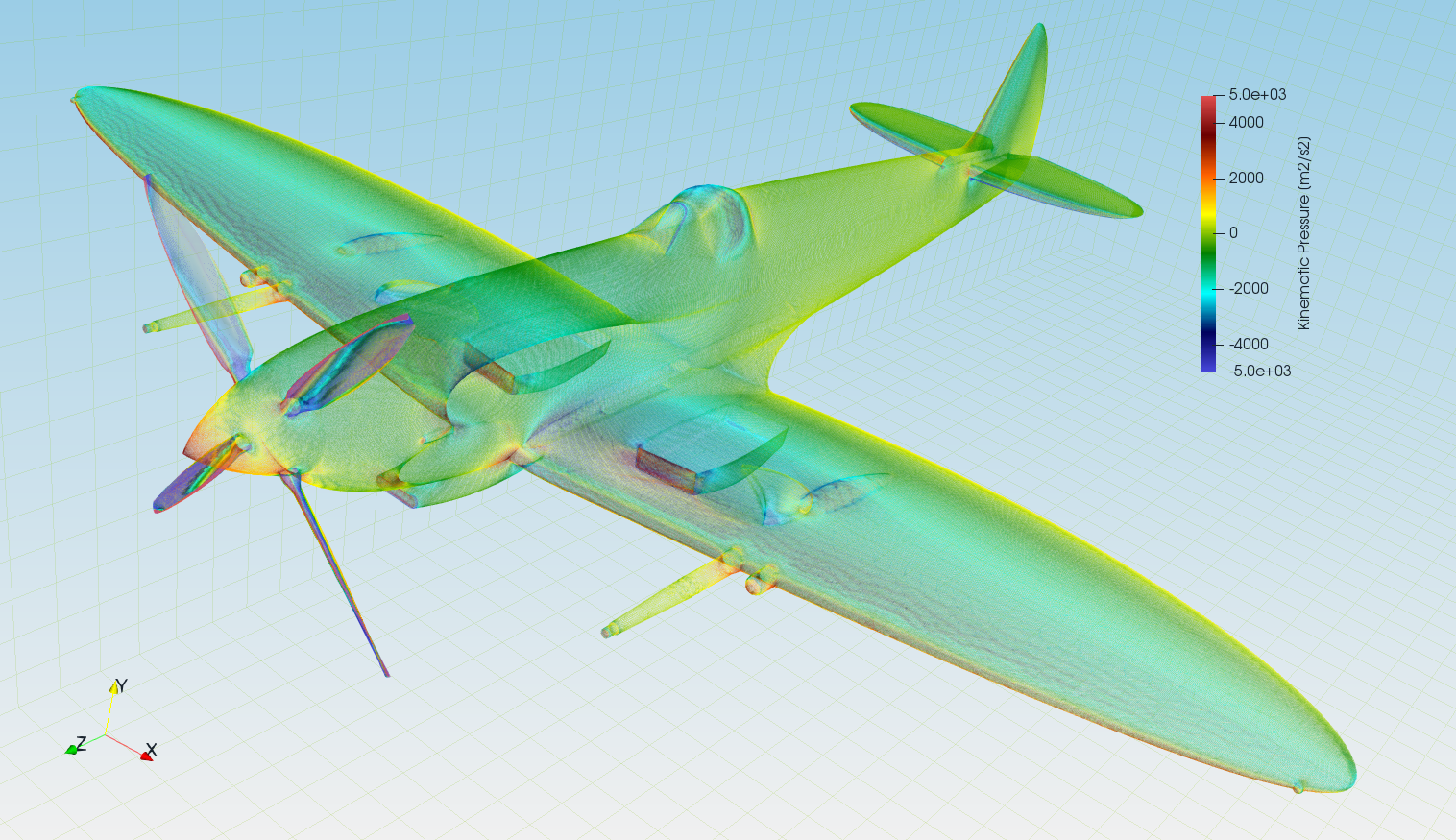

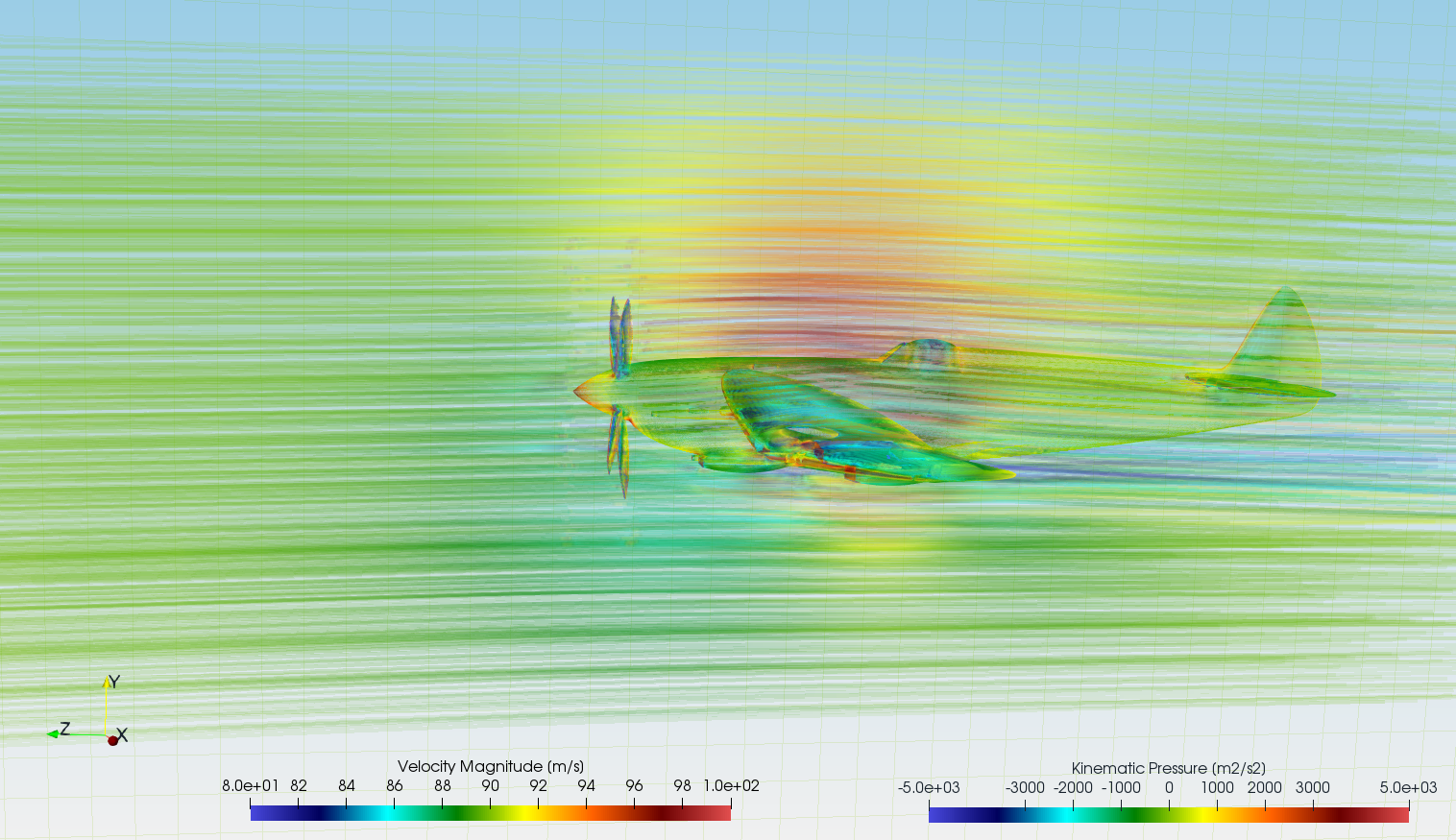

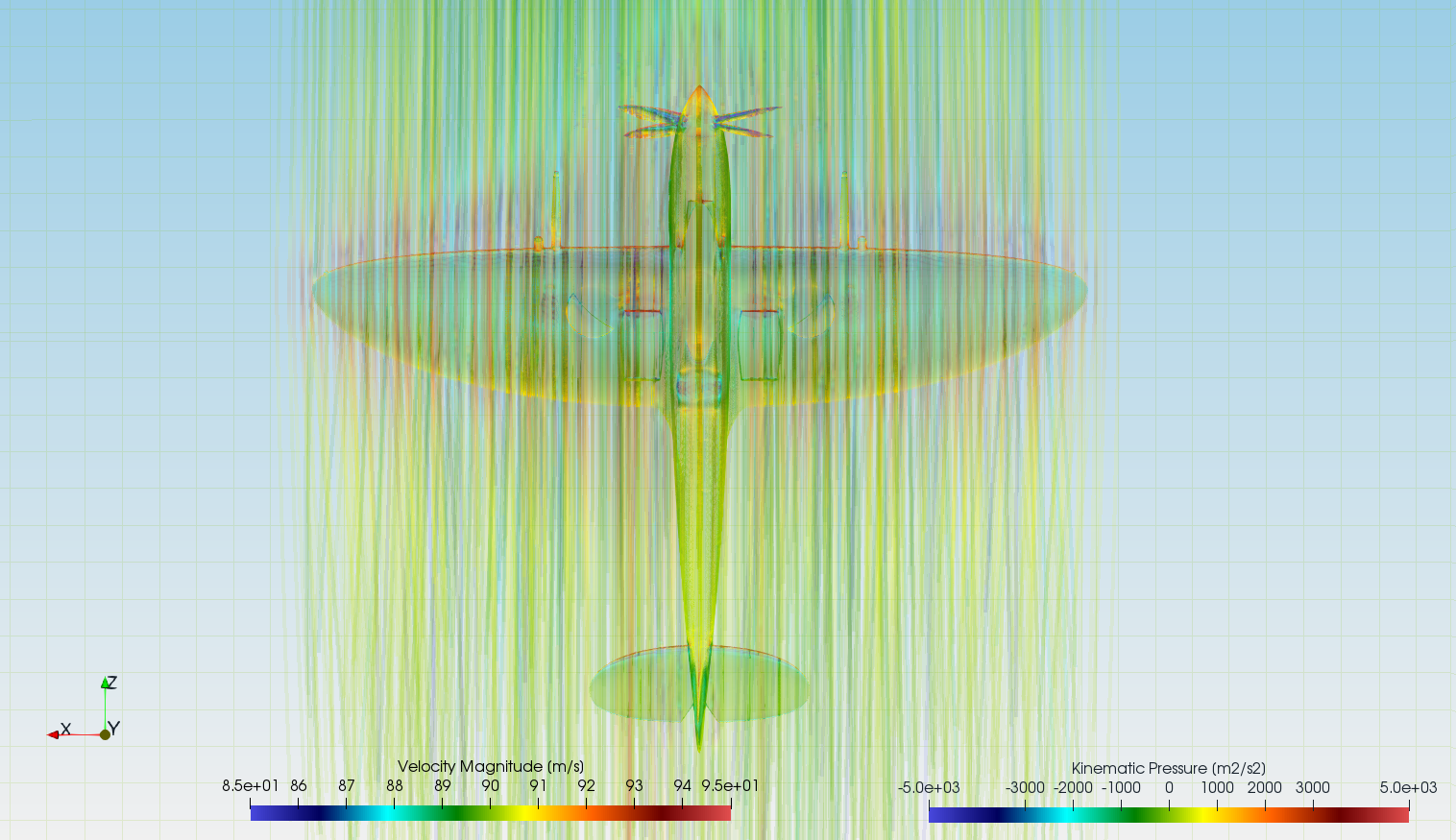

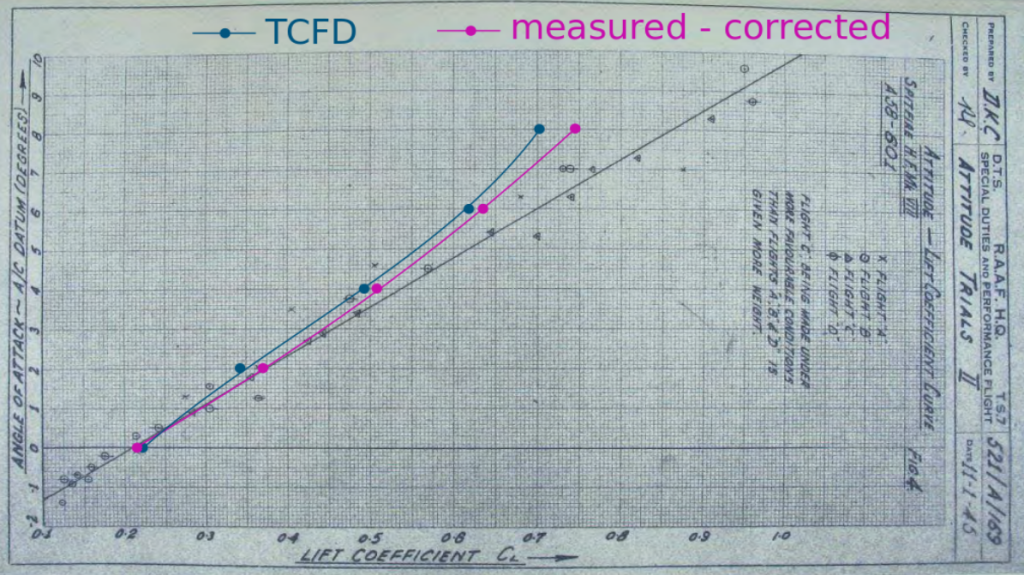

Test case - Supermarine Spitfire Mk VIII

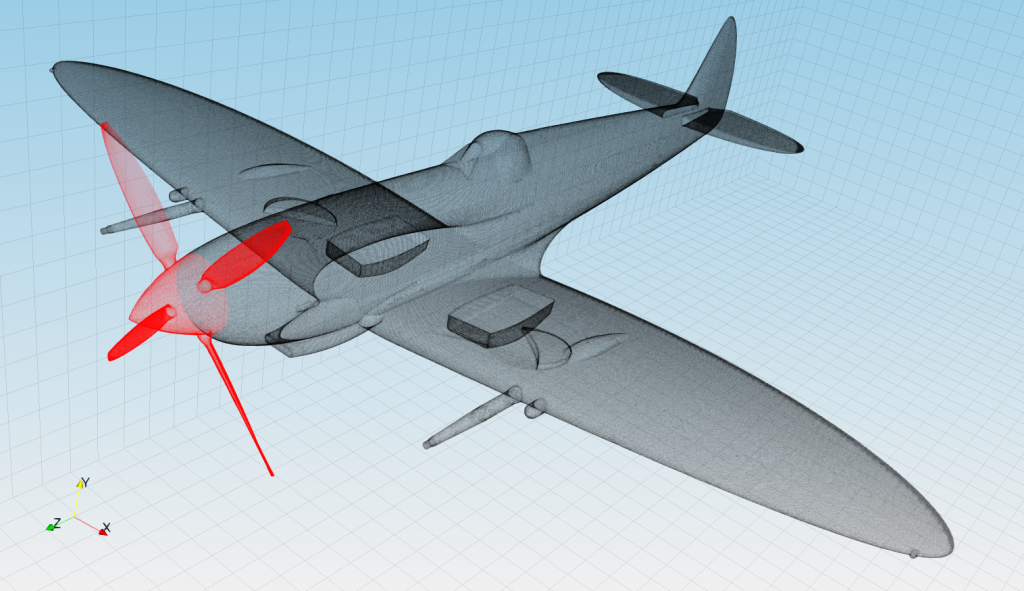

In this study it is shown how TCFD can be applied on an aircraft simulation. Supermarine Spitfire is famous British fighter used by Royal Air Force during World War II and belongs to the most famous airplanes of all time. More than 20,000 pieces were produced in 24 main variations. That makes Spitfire one of the most produced fighters, also aircrafts, of all time. For our purposes we have chosen a model Spitfire Mk VIII, which CAD model is freely available at GrabCAD. Basic specifications of this particular version are given in the table below.

Preprocessing

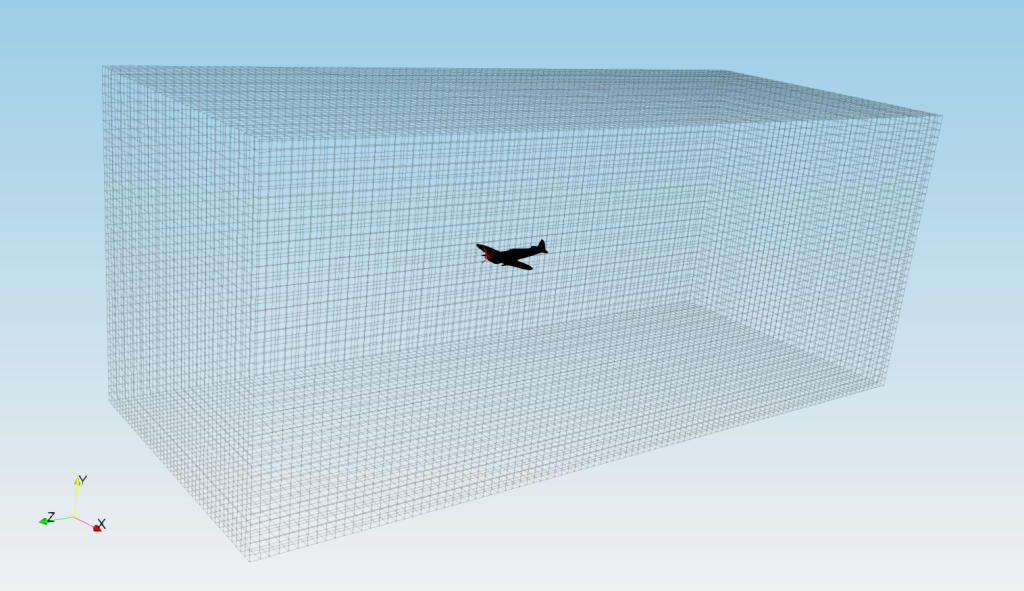

We started with a CAD model of Spitfire in file format STEP. For a professional CFD simulation, the original STEP file is usually too complex and therefore certain preprocessing work has to be done. Using an open-source software Salome, the model is simplified and cleaned. Some tiny and problematic parts are removed. The final surface model is made waterproof. An artificial “cylinder” surrounding the propeller is created, because of the propeller rotation. Another artificial objects is a “bounding box”, which will works as a virtual wind tunnel (domain boundary), so one can prescribe the boundary conditions. Finally, 2D surface meshes are generated to fit the CAD surface in an acceptable way. Individual STL files, that define the surfaces of the aircraft, bounding box and cylinder are exported. Remember, the preprocessing is extremely important for each CFD workflow. Preprocessing always limits the CFD results and sets the expectations.

Input data

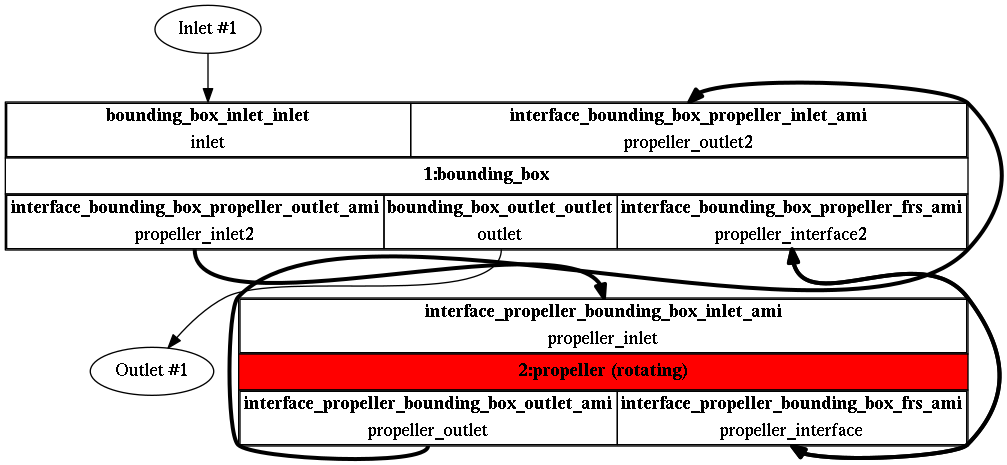

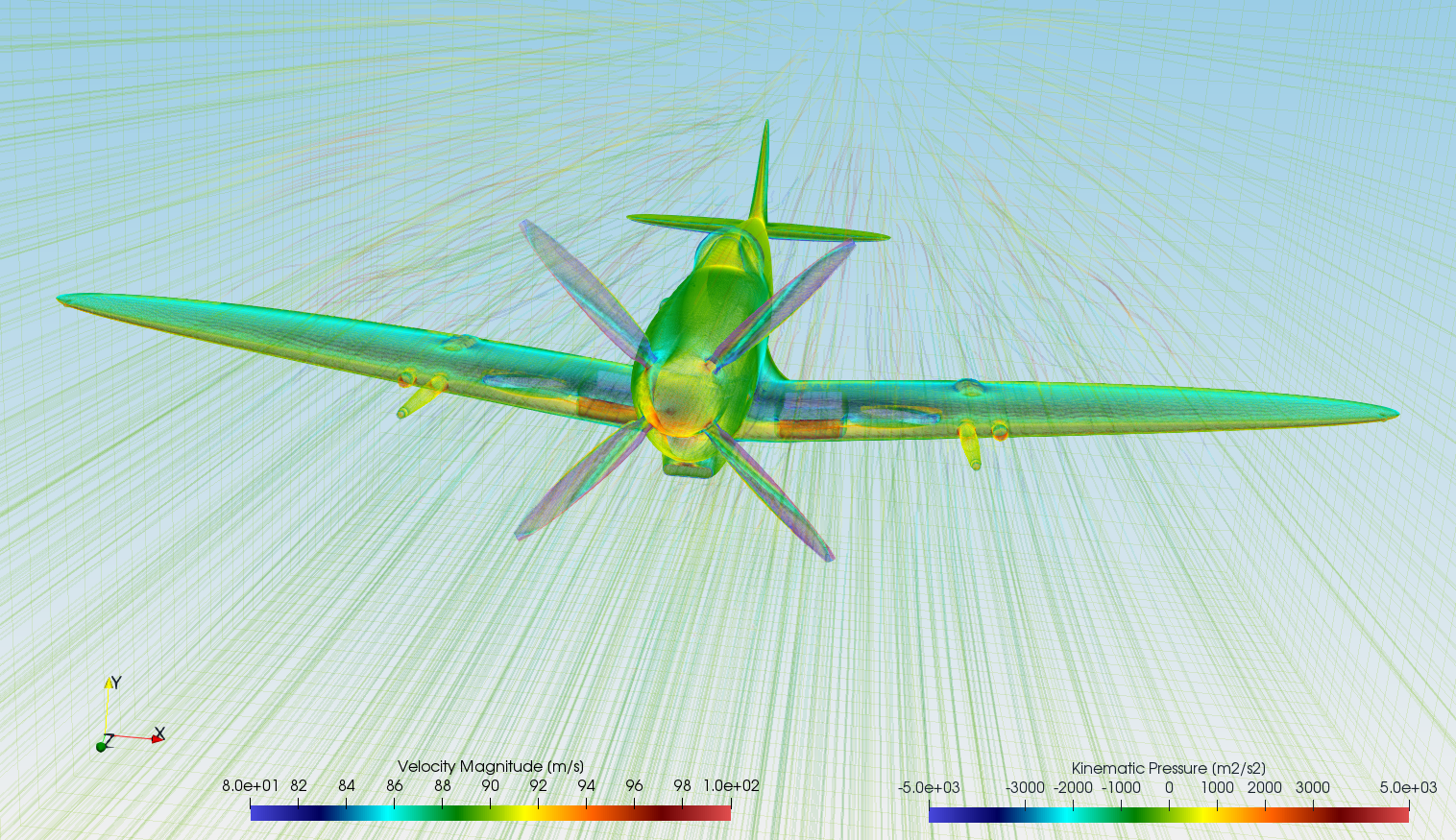

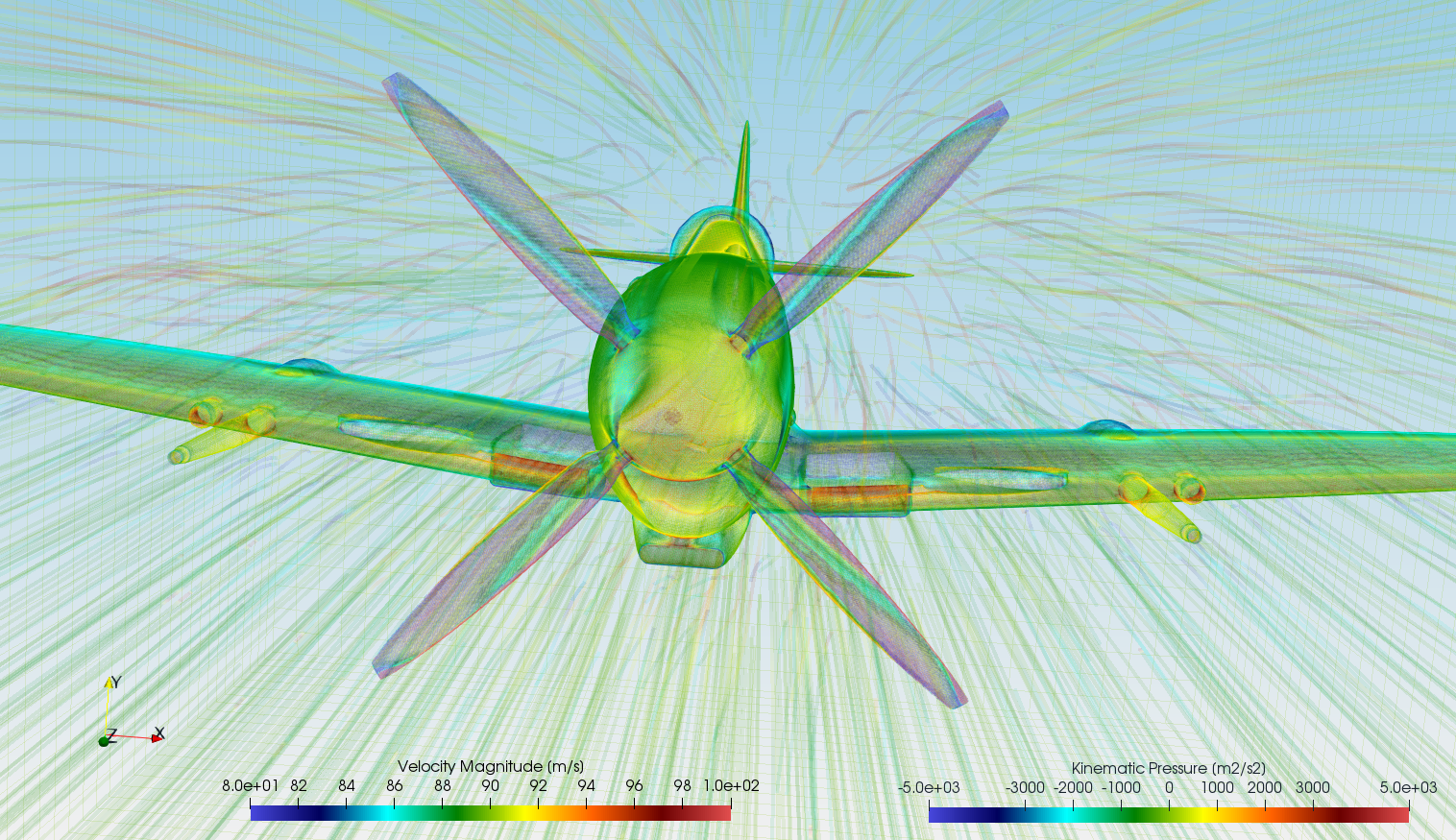

The surface model data in .stl file format together with physical inputs are loaded in TCFD. Other option would be loading an external mesh in OpenFOAM® mesh format, or loading an MSH mesh format (Fluent mesh format). This CFD methodology employs a multi component approach, which means the model is split into a certain number of regions. In TCFD each region can have its own mesh and individual meshes comunicate via interfaces.

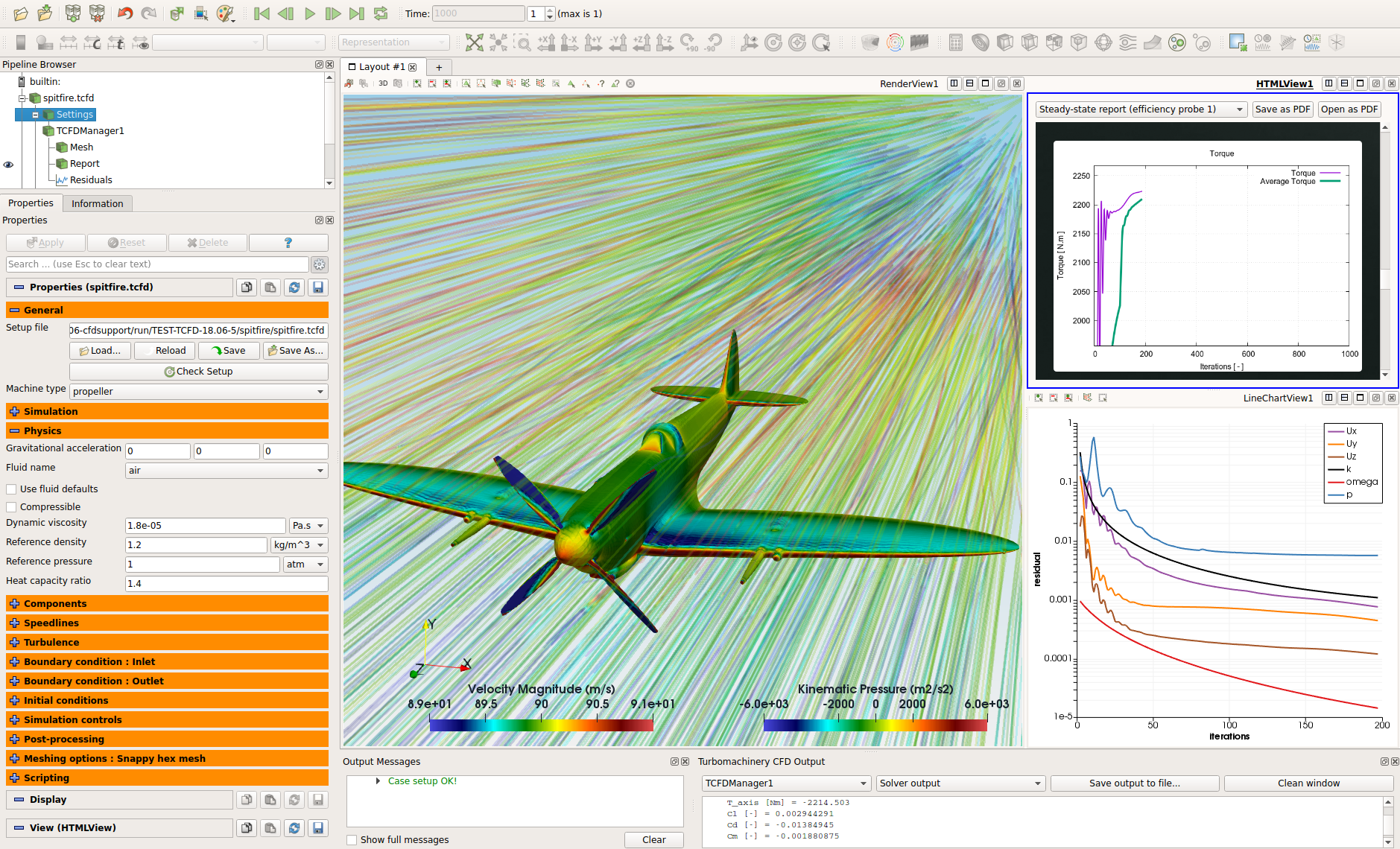

Grapgical interface

Mesh

In this particular case, the simulation model is split into two components. The Propeller in cylinder and the rest of the domain. Each component has its own mesh. All the meshes are created automatically for each component within snappyHexMesh. Any number of model components is allowed.

The component graph

Any project simulated in TCFD has its component graph. The component graph shows how the components are organized – the model topology. What is the inlet, the outlet and how the components are connected via interfaces.

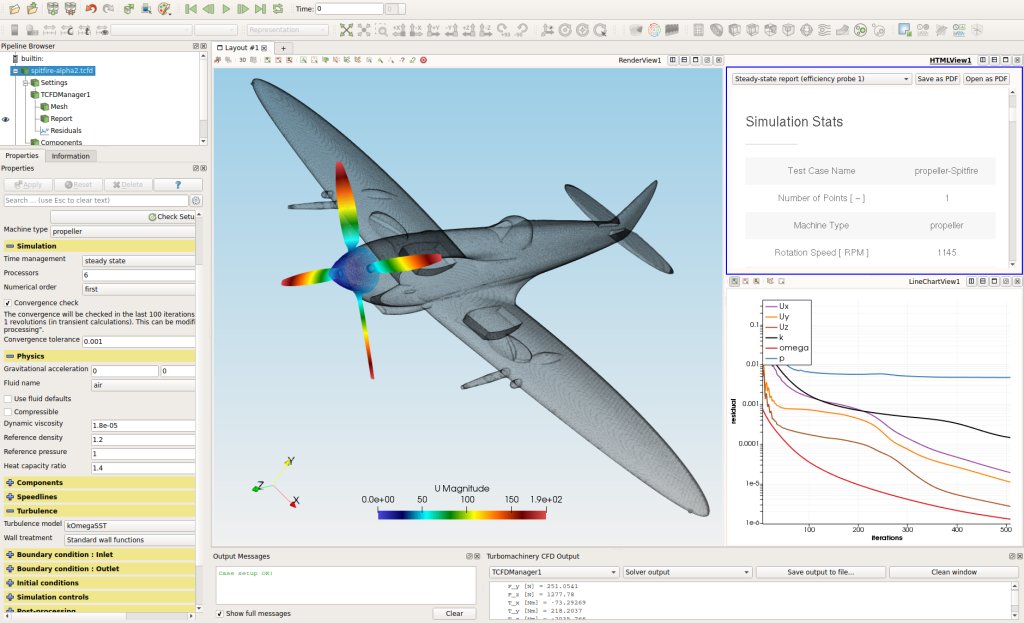

CFD Simulation Set-up

- Incompressible & Compressible flow model

- Steady-state flow model

- Medium: Air

- Viscosity: μ = 1.831e-5 [Pa.s]

- Rotation speed: 1145 [RPM]

- Flow Velocity: 90 [m/s]

- Interface: freestream - solid body motion (no averaging)

- Turbulence Model: k-ω SST

- Mesh: Mix snappyHexMesh - hexa

- Mesh Cells: 6,291,999

- Mesh Average y+ (full/segment): 322 [-]

- CPU time (steady-state): 6.5 [core.hours]

For more details of CFD Simulation Set-up see TCFD Manual.

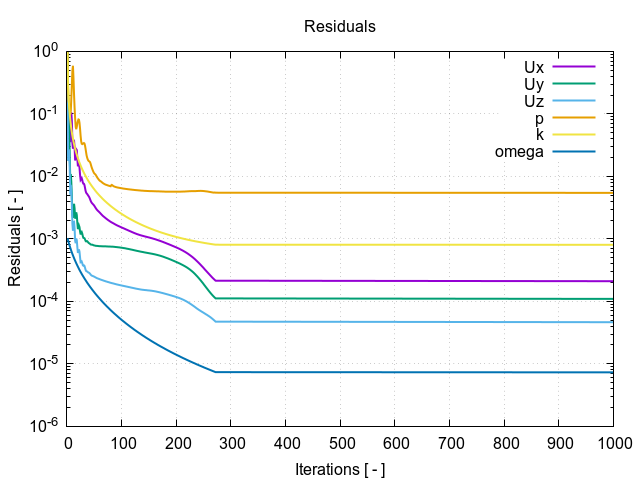

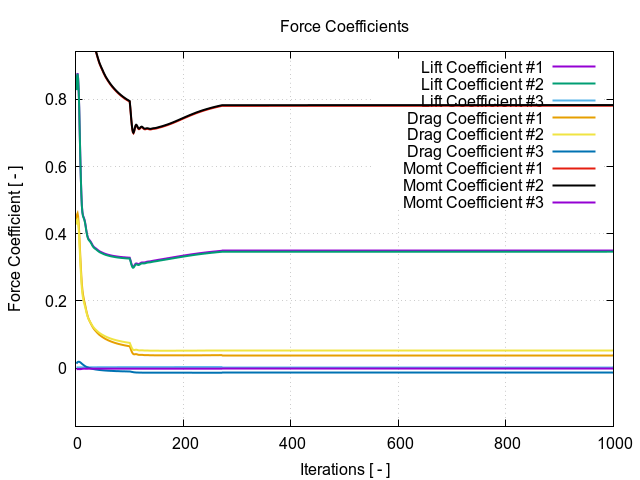

Running CFD Simulation

The simulation can be run on any number of parallel processors. Immediately after the simulation is started, the user can follow the progress of all the important quantities in a HTML report: flow rates, residuals, efficiency, torque, pressure difference and many others. These run-time functions give the user valuable information of the simulation convergence and also the availability to stop the simulation before its expected end.

Every simulation performed in TCFD has its report in web responsive .html and pdf format: Spitfire – Results Report.

Please contact us for further information.

Download TCAE Tutorial - Spitfire Benchmark

File name: Spitfire-TCAE-Tutorial-21.09.zip

File size: 5 MB

Tutorial Features: CFD, TCAE, TMESH, TCFD, SIMULATION, TURBOMACHINERY, EXTERNAL AERODYNAMICS, INCOMPRESSIBLE FLOW, RANS, STEADY-STATE, AUTOMATION, WORKFLOW, RADIAL FLOW, FULL IMPELLER, SNAPPYHEXMESH, 3 COMPONENTS, RPM=1145