Previous: Instant convergence monitoring during Up: Test case: motorBike Next: Function probe

This is an automatically generated documentation by LaTeX2HTML utility. In case of any issue, please, contact us at info@cfdsupport.com.

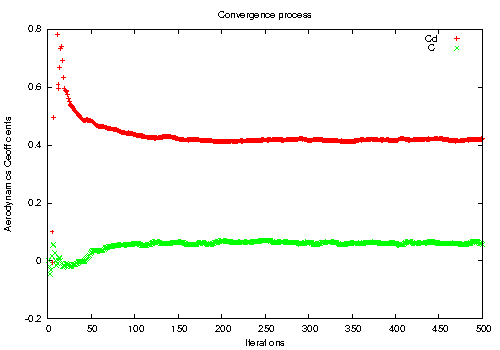

Aerodynamic coefficients  and

and

- Aerodynamic coefficients

and

and  can be evaluated by adding additional functions to controlDict file

can be evaluated by adding additional functions to controlDict file - Configuration file controlDict is extended:

/*--------------------------------*- C++ -*----------------------------------*\ | ========= | | | \\ / F ield | OpenFOAM: The Open Source CFD Toolbox | | \\ / O peration | Version: dev | | \\ / A nd | Web: www.OpenFOAM.org | | \\/ M anipulation | | \*---------------------------------------------------------------------------*/ FoamFile { version 2.0; format ascii; class dictionary; object controlDict; } // * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * // application simpleFoam; startFrom latestTime; startTime 0; stopAt endTime; endTime 500; deltaT 1; writeControl timeStep; writeInterval 100; purgeWrite 0; writeFormat binary; writePrecision 6; writeCompression uncompressed; timeFormat general; timePrecision 6; runTimeModifiable true; functions { #include "streamLines" #include "cuttingPlane" #include "forceCoeffs" } // ************************************************************************* // - Object libs and includes of files streamLines and cuttingPlane can be deleted for this time. File forceCoeffs reads as follows:

/*--------------------------------*- C++ -*----------------------------------*\ | ========= | | | \\ / F ield | OpenFOAM: The Open Source CFD Toolbox | | \\ / O peration | Version: dev | | \\ / A nd | Web: www.OpenFOAM.org | | \\/ M anipulation | | \*---------------------------------------------------------------------------*/ forceCoeffs1 { type forceCoeffs; libs ("libforces.so"); writeControl timeStep; timeInterval 1; log yes; patches (motorBikeGroup); rho rhoInf; // Indicates incompressible rhoInf 1; // Redundant for incompressible liftDir (0 0 1); dragDir (1 0 0); CofR (0.72 0 0); // Axle midpoint on ground pitchAxis (0 1 0); magUInf 20; lRef 1.42; // Wheelbase length Aref 0.75; // Estimated /* binData { nBin 20; // output data into 20 bins direction (1 0 0); // bin direction cumulative yes; } */ } - forceCoeffs1 computes coefficients

and

and  in direction liftDir and dragDir, data are saved after each time step in directory postProcessing/forceCoeffs1

in direction liftDir and dragDir, data are saved after each time step in directory postProcessing/forceCoeffs1 - Easy Gnuplot script named e.g. plotCdCl displays

and

and  development:

development:# Gnuplot script file for plotting data from file "forceCoeffs.dat" set title "Convergence process" set xlabel "Iterations" set ylabel "Aerodynamics Coefficients" plot [ ][-0.2:0.8]\ "postProcessing/forceCoeffs1/0/forceCoeffs.dat" using 1:3 title 'Cd', \ "postProcessing/forceCoeffs1/0/forceCoeffs.dat" using 1:4 title 'Cl' pause mouse - Run the script:

# gnuplot plotCdCl

Previous: Instant convergence monitoring during Up: Test case: motorBike Next: Function probe

![Node147 36 [*]](https://www.cfdsupport.com/wp-content/uploads/2022/02/crossref.png)